Within an ecosystem where by even the slightest miscalculation may result in critical harm, it can be essential to possess essentially the most Innovative and correct forklift pedestrian safety program Prepared for the team.

Obtaining satisfactory illumination not only enhances the productivity with the forklift operator but additionally fulfills the visibility needs of various people. By way of example, older operators may need much more light to work a forklift safely and securely.

Forklifts are usually Outfitted with tail or brake lights at the same time. But if a forklift did not originate from the company Geared up with tail/brake lights, OSHA does not need you to retrofit your truck.

The same principle applies to your office at the same time. Pedestrian safety while in the warehouse not simply depends around the attentiveness from the forklift operator but additionally the awareness and caution of the pedestrians them selves.

Safeguarding the safety of pedestrians starts off by establishing acceptable safety procedures and educating forklift operators on safe procedures.

The Occupational Safety and Wellbeing Administration (OSHA) is actually a regulatory system that sets and enforces laws and criteria to protect the effectively-currently being of personnel and reduce injuries.

This basically implies that you have to take some time to meticulously and precisely evaluate your Functioning environment right before choosing what lights need to be placed on your forklift.

If pedestrians and operators only think about the ground for lights, They could skip warning indicators and Seems all-around them.

Do you need any of such forklift lights? The limited answer is: it relies upon. The optional lights you place on your forklifts will depend upon your particular Procedure.

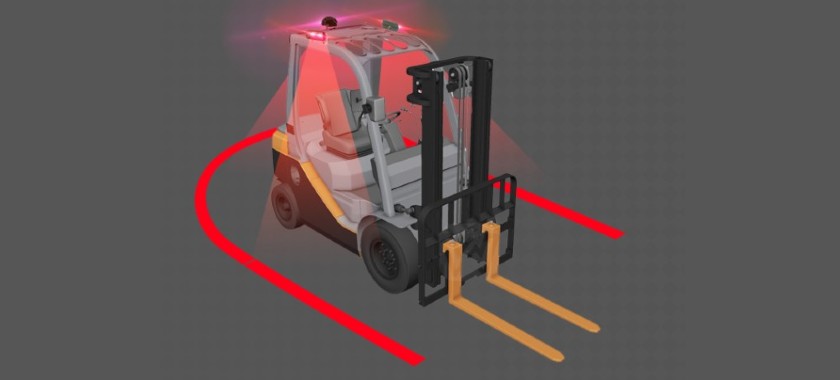

The halo forklift lights safety zone produces a singular separation between pedestrians and forklifts. It generates a visual boundary, reminding pedestrians to maintain a safe distance with the forklift. This separation lowers the chances of mishaps and accidents.

Visible inspection: Operators need to inspect the forklift for virtually any obvious signals of injury, such as leaks or worn-out tires.

Actions like complete schooling, products maintenance, obvious signage, Protected velocity boundaries, and safety audits contribute to the safe workplace. Continual advancement and ongoing instruction preserve safety to be a prime priority, preserving staff educated about forklift forklift lights safety operation risks.

Depending upon the angle, the blue light-weight shines ten to twenty toes from the forklift and moves alongside the ground since it travels, forklift lights safety indicating the place and how briskly you happen to be traveling.

As engineering advances, We could count on to determine far more thorough safety attributes forklift lights safety extra to forklift engineering in order to even further improve workplace safety in industries that count forklift lights safety on these important automobiles.